Why Choosing the Right Material Matters: The Key to Waterproof and Breathable Balance

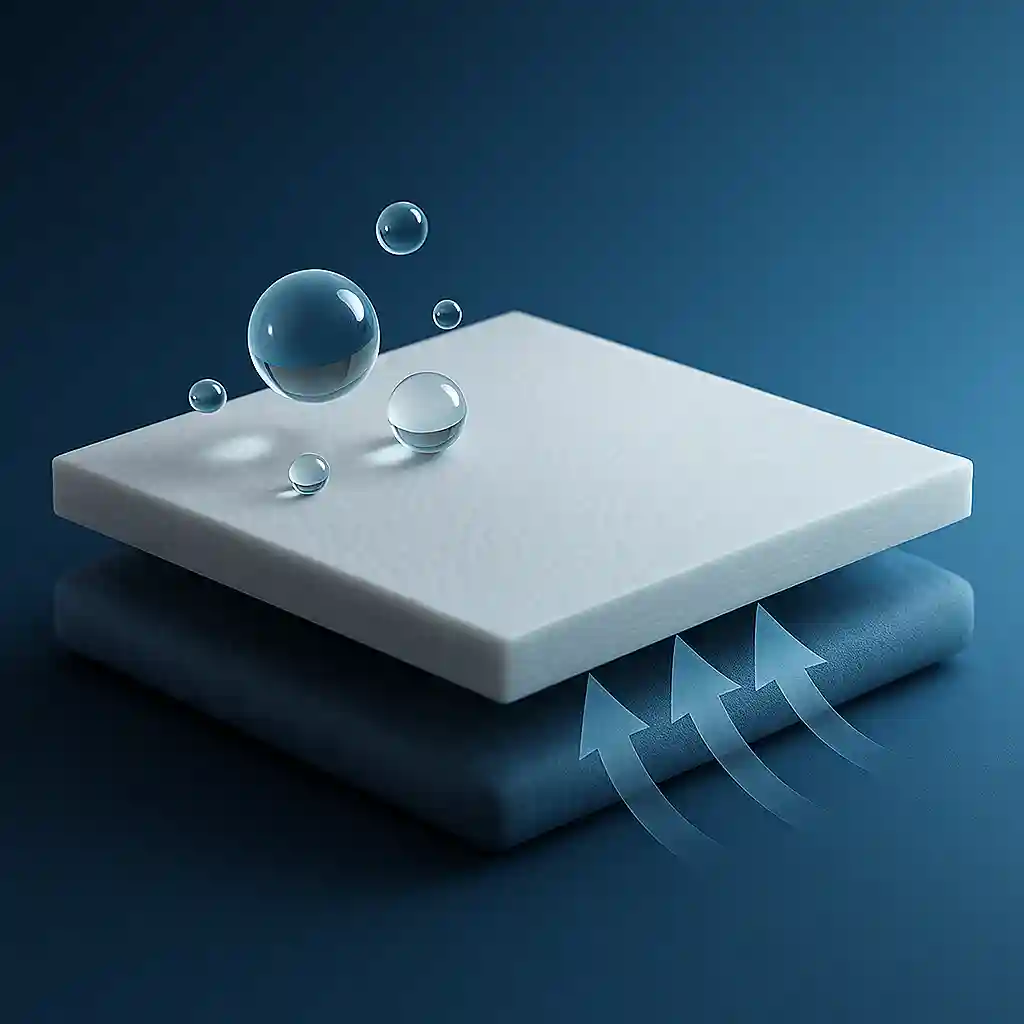

When a raindrop settles on a fabric yet never travels inside, and when heat and humidity build up only to be released a moment later, the effect is not magic. It is engineered balance: waterproofing and breathability working together.

At Kae Hwa, we are dedicated to perfecting this balance. From everyday apparel to medical protection, from car covers to construction membranes, our materials are designed so protection and comfort do not compete—they reinforce each other.

Why Choosing the Right Material Matters: The Key to Waterproof and Breathable Balance

You might think:

“A raincoat only needs to block rain, and a car cover must be waterproof—so why worry about breathability?”

In practice, waterproofing and breathability are interdependent. The right membrane must do both, or long-term performance suffers.

- Block external moisture to protect structures and contents from rain, splashes, or chemical exposure.

- Release internal moisture and heat to keep surfaces dry, extend service life, and prevent mold or corrosion.

Which function leads depends on the application:

- Outdoor performance apparel and rain gear: Without vapor release, sweat accumulates and comfort drops; a damp microclimate can even encourage microbial growth.

- Car covers and equipment tarps: Daily temperature swings drive condensation under non-breathable layers, causing rust and coating damage.

- Building waterproofing membranes: In wood or composite wall assemblies, trapped vapor can warp components and cut insulation efficiency, compromising safety.

- Medical and hygiene products: Gowns that only repel liquid trap heat and moisture, increasing skin irritation and lowering user compliance during long wear.

Kae Hwa integrates both functions within a single layer, using microporous PE and PP membranes. Carefully controlled pore size allows vapor molecules to pass while blocking liquid water, ensuring reliable waterproof and breathable performance.

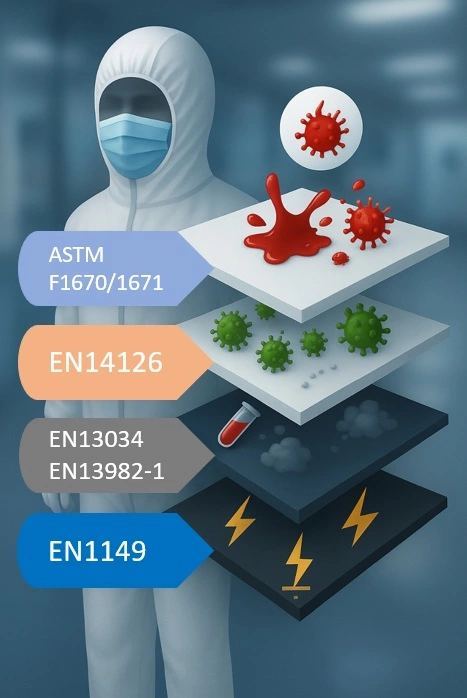

International Standards for Waterproof and Breathable Materials — What Matters

Feel or thickness alone does not prove reliability. Consistent performance is demonstrated through recognized test methods:

- ASTM F1670 / F1671: Synthetic blood and viral penetration tests, widely used for medical protective fabrics.

- EN 14126: Pathogen protection performance for isolation and protective apparel.

- EN 13034 (Type 6) / EN 13982-1 (Type 5): Liquid splash and hazardous dust barrier evaluation for chemical and industrial settings.

- EN 1149: Electrostatic discharge protection.

- ISO 9001: Quality management certification to ensure traceable, continuously improved manufacturing.

Every Kae Hwa fabric and film is verified against these benchmarks—our commitment to proven performance, not assumptions.

Our Principle: Performance Driven by Data, Not Assumptions

A membrane’s value cannot be judged by look or hand feel. At Kae Hwa, we insist on three things:

-

Quantitative data

Key properties—including MVTR (Moisture Vapor Transmission Rate), hydrostatic resistance, tensile strength, and wash durability—are confirmed by independent laboratory reports.

-

Tailored formulations

We select single-layer films, microporous membranes, or composite constructions based on MVTR targets, chemical resistance, mechanical strength, and downstream converting needs.

-

Continuous R&D optimization

Any off-spec result triggers reformulation or process tuning in the lab until the standard is consistently met, lot after lot.

This approach ensures stable waterproof and breathable performance under demanding conditions across medical, industrial, construction, and outdoor environments.

Want to Learn More About Our Products and Testing?

Kae Hwa provides technical data sheets, test reports, and OEM/ODM customization. Whether you are building medical protection, industrial solutions, or outdoor performance products, we support film selection, lamination windows, and wide-width slitting to meet specific requirements.

👉 Click to explore our products and testing resources

FAQ

Q1: How do waterproof and breathable materials work?

By blocking liquid water while allowing water vapor to pass. In microporous PE and PP membranes, this is achieved through a fine pore network: vapor molecules move through the pores, while liquid water is prevented from passing due to surface tension and pore size control.

Q2: What is the difference between ASTM F1671 and EN 14126?

ASTM F1671 assesses resistance to viral penetration using synthetic blood. EN 14126 evaluates protective clothing against a broader set of pathogens. Both are commonly applied to medical-grade fabrics.

Q3: Can Kae Hwa’s materials be customized?

Yes. We offer OEM/ODM services—including structure design, coating formulation, lamination selection, and post-processing—tailored to end-use requirements.

Q4: Which industries use these membranes?

Applications include medical protection (surgical gowns, isolation wear), industrial safety (chemical suits, dust covers), outdoor performance apparel, building waterproofing membranes, desiccant packaging, and personal hygiene products.

Language

Language