Combining High Performance and Circular Recycling in TPEE Laminated Fabrics

Combining High Performance and Circular Recycling in TPEE Laminated Fabrics

The global textile industry is in the midst of rapid change. Today's consumers expect both advanced technical performance and genuine environmental responsibility—mere waterproofing or basic comfort is no longer enough.

Within this trend, TPEE (Thermoplastic Polyester Elastomer) laminated fabrics, which deliver waterproof, breathable and moisture-wicking performance, are emerging as a key material for the next generation of outdoor and urban functional apparel.

Traditional waterproof textiles often rely on polyurethane coatings or multiple chemical finishes. These treatments can block rain, but they typically sacrifice breathability and use chemical solvents that raise environmental and health concerns.

TPEE lamination offers a better path forward: it provides strong, long-lasting protection while allowing body moisture vapor to escape. At the same time, its dual-cycle recycling system dramatically reduces environmental impact—an important milestone as the textile industry moves toward true sustainability.

A High-Performance Choice — Windproof, Waterproof and Moisture-Wicking

How the Microporous Structure Works

The secret behind TPEE film is its selective permeability. Across the film's surface are countless nano-sized micropores:

- The pores are far smaller than clusters of liquid water molecules, effectively blocking rain and external moisture.

- Water-vapor molecules are much smaller and can freely pass through the film.

This mechanism keeps garments dry and comfortable even during intense activity, preventing the sticky, clammy feel caused by trapped sweat.

Proven Breathability and Hydrostatic Resistance

Independent testing to ASTM E96 BW and JIS L 1099 A1 standards shows that TPEE film reaches a moisture vapor transmission rate (MVTR) of 10,000–20,000 g/m²·24 hr.

Its hydrostatic head exceeds 10,000 mmH₂O, more than enough to handle prolonged heavy rain or snowy conditions.

In practice, this means the fabric delivers reliable wind and rain protection while quickly releasing perspiration—ideal for outdoor and athletic apparel.

Comfort and Durability Over Time

The natural elasticity and softness of TPEE give laminated fabrics a light weight and smooth drape.

Unlike traditional coated textiles, TPEE membranes retain their waterproof and breathable performance even after repeated washing and abrasion, without peeling or flaking.

This longer service life means fewer replacements as performance declines, which in turn reduces overall textile waste.

Where It Performs

- Outdoor Activities: Perfect for long hours in unpredictable weather—whether mountain trekking, winter skiing or long-distance cycling. TPEE laminates keep out rain and snow while letting perspiration escape, so wearers stay dry and avoid the discomfort or cold stress caused by trapped moisture. Even at high altitudes or in rapidly changing humidity, the microporous structure remains stable, ensuring jackets and shell garments provide dependable wind and rain protection throughout the trip.

- Urban Daily Wear: For city commuting and everyday style, the same waterproof and breathable qualities are just as valuable. During sudden downpours or passing cold fronts, coats or stylish rain jackets made with TPEE laminated fabric shield against rain while preventing heat and moisture build-up. Unlike traditional plastic raincoats, their soft hand-feel and light weight make them comfortable for daily wear—from office commutes to weekend outings—balancing modern style with true all-weather protection.

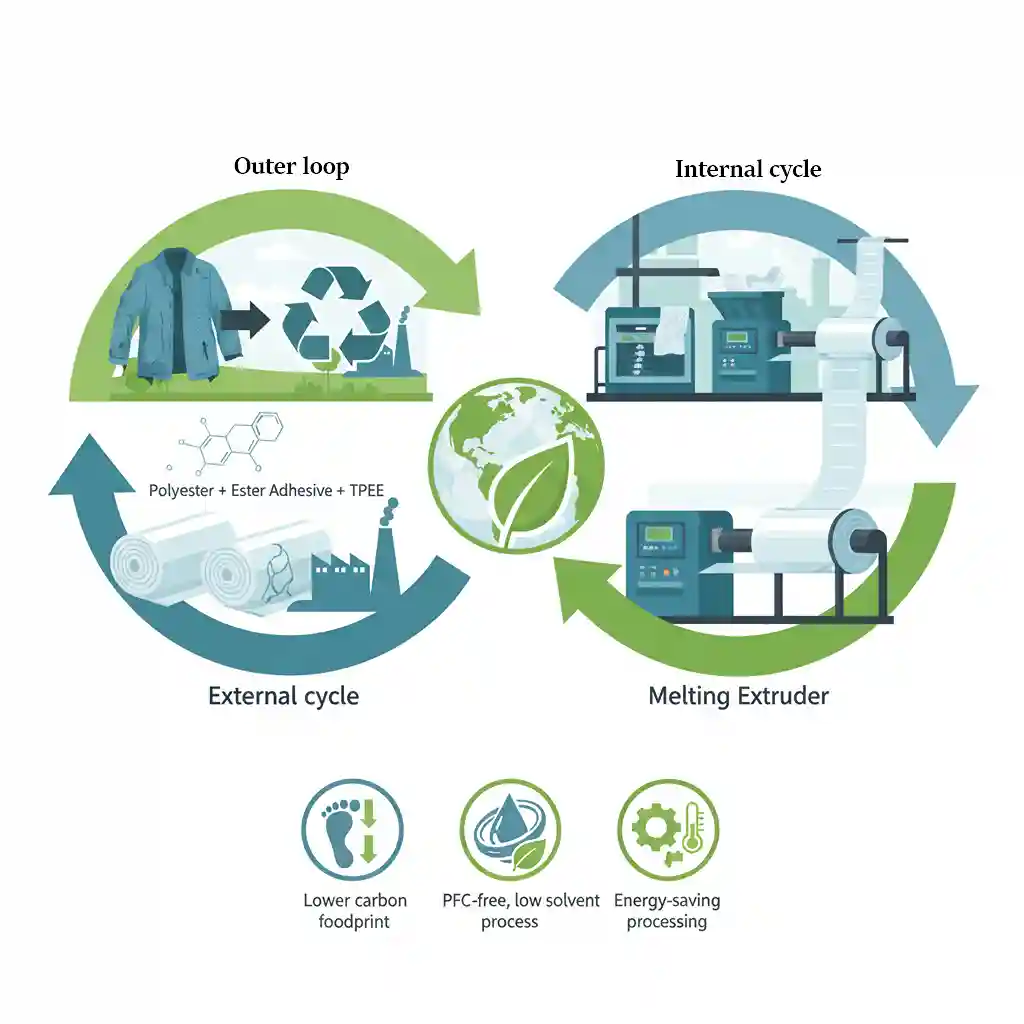

Closing the Loop — A Dual-Cycle Recycling System

Outer Loop: Mono-Material Design

TPEE laminated fabrics combine polyester, an ester-based adhesive and a TPEE functional membrane in a mono-material structure.

This single-material design allows finished products to enter recycling systems at the end of their life without complex layer separation. Compared with traditional multi-layer composites, TPEE laminates are easier to recover and turn back into raw material.

Inner Loop: Zero-Waste Production

During production, edge trims and off-spec films are shredded, blended and re-extruded into new functional film.

This inner loop reduces the need for virgin raw materials and turns production waste back into usable resources, moving the entire process toward a zero-waste goal.

Lowering Carbon Impact

- Reduced Carbon Footprint: Recycling and reprocessing cut dependence on virgin petrochemical feedstocks.

- PFC-Free, Low-Solvent Process: Avoids per-fluorinated compounds and minimizes solvent emissions, preventing long-term environmental pollution.

- Energy-Efficient Lamination: Low-temperature processing lowers energy use while maintaining strong, durable bonding.

A Sustainable Future and Market Opportunities

From Outdoor Sports to Urban Fashion

The global outdoor-apparel market continues to grow as consumers seek all-weather protection with all-day comfort.

Lightweight, soft and highly breathable, TPEE laminated fabrics are a natural fit for both performance sports gear and stylish urban outerwear, combining functionality and design appeal.

A Circular-Economy Model for Textiles

From raw-material selection to waste recycling, TPEE laminated fabrics embody the principles of a circular economy:

- Reduce the use of virgin resources

- Reuse production waste through dual-cycle recycling

- Provide verifiable recycled content to help brands meet ESG and sustainability goals

Kae Hwa has earned the GRS (Global Recycled Standard) 4.0 Scope Certification, confirming that our production processes meet international standards for recycled-content management and environmental practices. On request, we can issue a Transaction Certificate (TC) with each shipment to verify the source and percentage of recycled material.

This internationally recognized certification strengthens the credibility of our circular-economy approach and builds trust across the green supply chain.

Applying circular-economy principles not only reduces environmental impact but also provides the textile industry with an effective strategy for meeting global carbon-reduction and sustainable-supply-chain requirements.

Value for Brands and Consumers

For brands, selecting TPEE laminated fabrics means integrating sustainability and performance into product design from the outset.

For consumers, these fabrics deliver comfort, dependable weather protection and a responsible choice for the planet.

Whether for performance-focused outdoor enthusiasts or urban residents who value both style and sustainability, TPEE laminated fabrics strike the perfect balance.

Experience TPEE Laminated Fabrics at the 2025 Taipei Innovative Textile Application Show

We will showcase our TPEE laminated fabrics at the 2025 Taipei Innovative Textile Application Show, where we will demonstrate how waterproof breathability and circular recycling can be applied from the earliest stages of textile design.

Visitors can examine the fabric structure up close, meet our technical team, and receive detailed technical data and samples to see the complete sustainable process from raw materials to finished products.

FAQ

Q: Will recycling TPEE film affect its waterproof and breathable performance?

A: After shredding, blending and re-extrusion, the microporous structure remains stable. Waterproof and breathability performance stay comparable to virgin material and meet ASTM E96 and JIS L 1099 international test standards.

Q: Is the GRS certification for products or for the company?

A: Kae Hwa holds a GRS 4.0 Scope Certification at the factory level. This confirms our capability to produce products that meet GRS standards for recycled content. If customers need proof of recycled content for a specific batch, we can provide a Transaction Certificate (TC) with the shipment.

Q: What are the main application areas for TPEE laminated fabrics?

A: Kae Hwa's TPEE laminated fabrics are primarily used in outdoor applications—such as functional outdoor jackets and shell garments—and in everyday waterproof coats and stylish rain jackets, providing reliable protection and comfort in changing weather.

Q: Why are TPEE laminated fabrics considered more environmentally friendly?

A: The entire design—from raw materials to production—reduces environmental impact. The mono-material structure allows end-of-life products to enter recycling systems without complex separation, and the low-solvent, PFC-free lamination process lowers chemical pollution and carbon emissions.

Language

Language